Leistungsstarke Wärmeübertragungslösungen für alle Anforderungen Ihrer Branche.

API Schmidt Bretten: Führender Hersteller für Wärmetauscher

- Vielfältiger Einsatz in industriellen Anwendungen

- Plattenwärmetauscher & thermische Systeme

- Individuelle Beratung für Ihre Anforderungen

Seit über 140 Jahren vertrauen viele Branchen auf unsere Wärmeübertrager.

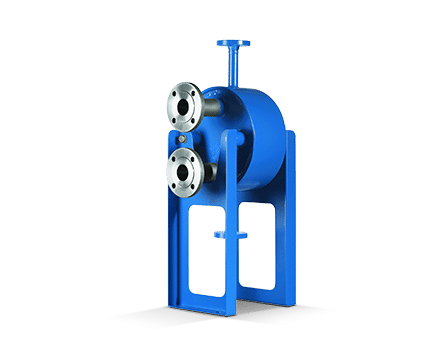

API Heat Transfer ist ein weltweit führender Hersteller von Wärmeübertragern in allen Größen und für alle industriellen Einsatzfelder. Unsere Produkte sind bekannt für ihr innovatives, technisches Design und ihre hervorragende Qualität. Das umfassende Serviceangebot wird von unseren Kunden sehr geschätzt.

Mit Vertriebsniederlassungen und Fertigungsstätten in allen Teilen der Welt bietet API Heat Transfer technologisch hochwertige Produkte mit regionalem Service.

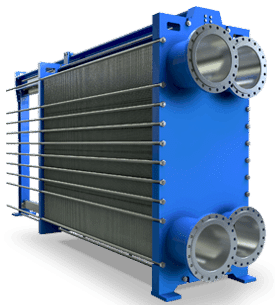

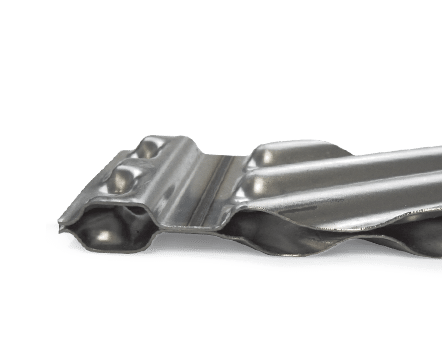

API Schmidt-Bretten ist ein weltweit anerkannter Hersteller gedichteter und geschweißter Plattenwärmeübertrager sowie von Systemen zur thermischen Behandlung pumpfähiger Medien in allen wichtigen Märkten.

Als Teil der API Heat Transfer Inc. decken wir die gesamte Spannweite von Produkten im Bereich Wärmeübertrager ab.

Folgen Sie uns auf eine Reise zwischen heiß und kalt, denn Austausch ist unsere Stärke !

Kontaktieren Sie uns noch heute und finden Sie heraus, was wir für Sie tun können.

Qualität und Zuverlässigkeit

Unsere Wärmetauscher sind nach höchsten Standards gefertigt und bieten eine zuverlässige Leistung in anspruchsvollen Umgebungen.

Kundenspezifische Lösungen

Mit unseren maßgeschneiderten Lösungen begegnen wir den spezifischen Anforderungen unserer Kunden.

Innovation und Technologie

Wir gehen mit den sich wandelnden Anforderungen unserer Kunden und haben den „State oft the Art“ bei den Wärmetauschlösungen immer im Blick.

Umfassender

Service

Von der Beratung und Auswahl des richtigen Wärmetauschers bis hin zur Installation, Inbetriebnahme und Wartung – unser erfahrenes Team ist stets an Ihrer Seite.

API Wärmeübertrager

Wir freuen uns auf den Kontakt mit Ihnen!

Genau dafür sind wir bekannt und für unsere Kunden da!

Lesen Sie hier mehr über unsere Arbeit und aktuelle Themen

Ausgewählte Fallstudie

SIGMATEC Entalkoholisierungssystem wird zum Brauen des mit Gold ausgezeichneten alkoholfreien Lagerbiers von Two Roots Brewing Brewing Co.™ eingesetzt

Two Roots Brewing Co. entalkoholisiert Bier mit dem Vakuumdestilationssystem von SIGMATEC, das den ursprünglichen Geschmack, die Farbe und das Aroma des Biers bewahrt.

Vorgestelltes Produkt

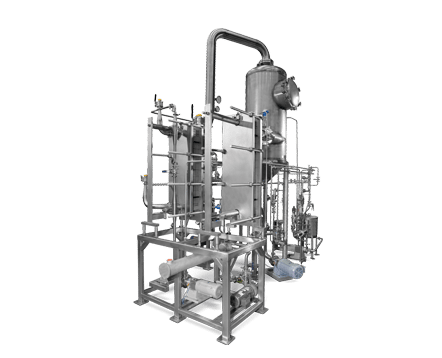

SIGMASTAR-Eindampfanlagen

Unsere Schmidt Bedampfungsanlagen mit SIGMASTAR® Kletterfilm-Plattenverdampfern werden in der Lebensmittelindustrie, in der organischen und chemischen Industrie sowie in der Abwasseraufbereitung eingesetzt.

Vorgeschlagene Nachrichten

Verbessern Sie Den Platzbedarf & Die Wirtschaftlichkeit Von Gas/Gas-Wärmeübertragern Mit Einem PSHE.

Dieser Artikel konzentriert sich auf eine spezifische Anwendung in Upstream-Anlagen, bei denen Gewichtsreduzierung und reibungsloser Betrieb im Turndown immer ein Anliegen ist. Der Konstruktionsvergleich, die Vorteile und die Grenzen zwischen S&T-Überträgern und PWTs werden anhand eines konkreten Beispiels vorgestellt und diskutiert.