Heat transfer solutions for process industries.

Productivity is important in key commercial industries, but it often comes at a cost to environmental safety. That isn’t the case with API Schmidt-Bretten products. We design high-performance solutions that can help with the clean, safe, and efficient management of industrial processes.

Our areas of expertise.

Wastewater treatment

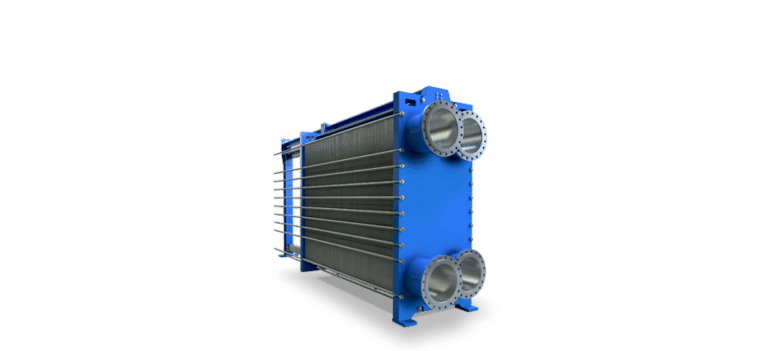

API Schmidt-Bretten’s advanced technologies and solutions can help with the safe and effective treatment of wastewater and waste, both of which have a direct impact on energy savings and environmental protection. Our SIGMASTAR evaporation systems can safely reduce the amount of wastewater, and our SIGMA plate heat exchangers can assist with heat recovery, so wastewater can be safely reused in other processes.

- Evaporation and concentration of coffee waste water

- Heat recovery systems for industrial wastewater

- Preheating and cooling of industrial wastewater

- Separation of solutions mixed with water such as ethanol / water

- Evaporation and concentration of waste water from the treatment of animal by-products

- Evaporation and concentration of wastewater from food production

Our products for Wastewater treatment

Chemical

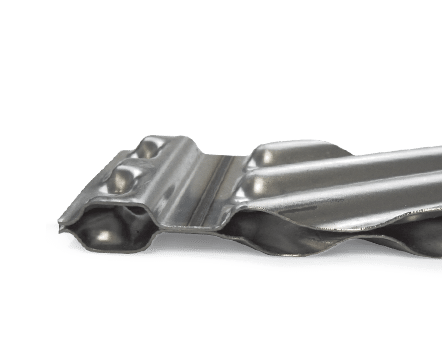

API Schmidt-Bretten is a recognized leader within the chemical industry, thanks to our decades-long track record of success with our Schmidt SIGMA plate heat exchangers. We provide solutions that offer superior efficiency and operational safety, low capital outlay, and flexible capacity for the most diverse applications, including cooling and heating of base, intermediate, and final products; heat recovery; and tempering of containers, reactors, and autoclaves.

Our plate heat exchangers have become an important component in many chemical production processes due to their capabilities in CIP or mechanical cleaning as well as their utilization of special materials for critical media. Our Schmidt SIGMASTAR® evaporators can be used for nearly all evaporation processes. They perform especially well for problem products, viscous streams, slurries, and liquids with fouling tendencies that cannot be processed with falling-film evaporators.

- Condensation of exhaust gas vapors, steam and multicomponent mixtures

- Cooling and heating at extreme temperatures and pressures

- Cooling and heating of acids and bases

- Cooling and heating of all types of jumpable chemical products

- Cooling of highly viscous products (i.e. latex)

- Cooling of water circuits

- Evaporation systems for sewage and waste solutions

- Intermediate and economizer circuits with high temperature similarity (Δt <2°C)

- Safety circuits to avoid contamination

- Temperature control and condensation of solvents (i.e. toluene)

Our products for Chemical

Refrigeration

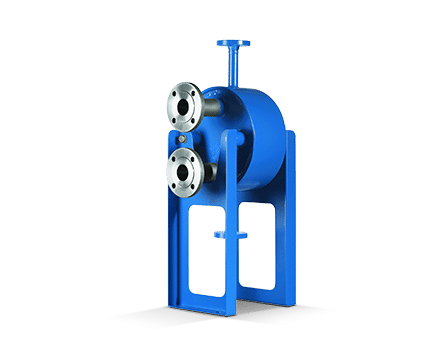

You can count on API Schmidt-Bretten to provide a full solution for your heat exchange needs in the refrigeration industry. For two decades, our plate heat exchangers have played a key role in the refrigeration process. With their compact construction and excellent thermal performance, they are an indispensable feature of today’s advanced refrigeration systems.

- Condensation of refrigerants

- Cooling of circuits

- Cooling of compressor oil

- Decoupling of refrigeration from central refrigeration circuits

- Evaporation of refrigerants

Our products for Refrigeration

Surface coating

Surface coating is performed for both aesthetic and functional reasons in processes that include painting furniture and chromium-coating parts of a vehicle. The coating fluids must be held to a specific temperature for proper application. API Schmidt-Bretten’s SIGMA plate heat exchanger solve this problem by ensuring fluids are heated to the right temperature during the industrial coating process.

- Baths

- Heating and cooling of anodizing, degreasing, phosphating, chromatin, pickling, passivating, heat sealing and painting batches

- Heating and cooling of products

Metal processing

With ever-increasing energy costs, customers working with steel and metals can count on API Schmidt-Bretten to deliver efficient heat recovery solutions. The cooling and tempering of different media for metal processing – such as grinding and cutting oils, emulsions, cooling water, and hydraulic oils – are among the main applications of our Schmidt SIGMA plate heat exchangers.

Thermal processing in metal construction uses quenching baths, which are filled with either oil or water. Since the heat generation is mostly higher than the bath is capable of absorbing through natural convection, the bath content must undergo a forced cooling process. That’s where the high efficiency of our plate heat exchangers can be counted on.

- Cooling and coking plants or stripping water

- Cooling of continuous casting plants

- Cooling of cutting and grinding oil

- Cooling of emulsions

- Cooling of mold water

- Cooling of machine cooling water

- Cooling of oil or water quenching baths

- Hydraulic oil cooling

- Temperature control of drilling, milling and planning emulsions

Our products for Metal processing

Surface coating

Surface coating is performed for both aesthetic and functional reasons in processes that include painting furniture and chromium-coating parts of a vehicle. The coating fluids must be held to a specific temperature for proper application. API Schmidt-Bretten’s SIGMA plate heat exchanger solve this problem by ensuring fluids are heated to the right temperature during the industrial coating process.

- Baths

- Heating and cooling of anodizing, degreasing, phosphating, chromatin, pickling, passivating, heat sealing and painting batches

- Heating and cooling of products

Our products for Surface coating

Petrochemical

No matter your petrochemical industry application, API Schmidt-Bretten can select the right solution that’s efficient in cost, space, and emission requirements.

Shell and tube heat exchangers have long played a role in petrochemical applications. Gasketed and fully welded plate heat exchangers have become increasingly important within the industry as well. We offer both shell and tube and plate technologies to our customers in the petrochemical industry.

When performance under extreme pressure and temperature conditions is critical, our specialized shell and tube heat exchangers are ideal. In fact, ours are regularly used in the most varied offshore and onshore plants.

Our plate heat exchangers – with their high pressure and temperature capabilities, unique materials, and special sealing qualities – are ideal for heat recovery tasks or the condensation of solvents.

- Benzene heat recovery

- Condensation of solvents and multicomponent mixtures

- Cooling and heating of intermediate products

- Cooling and heating of reactors and production vessels

- Cooling of hydrocarbons

- Cooling of water circuits

- Heat recovery in petrochemical processes

Our products for Petrochemical

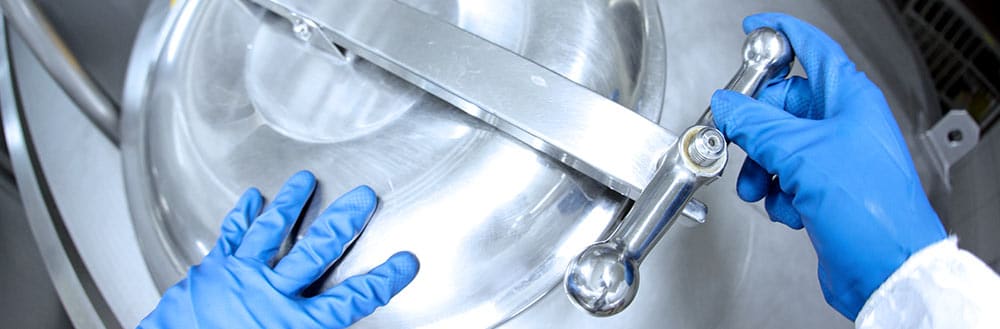

Pharmaceuticals, nutraceuticals, and cosmetics

The successful production of pharmaceuticals and cosmetics is tied to the purity of the intermediate and final products used during manufacturing. At API Schmidt-Bretten, we understand the need for the highest level of operational safety and security of all components at a manufacturing plant.

Our SIGMA plates with special surfaces are used to avoid precipitation in the flow space, and our PTFE-enveloped elastomeric gaskets demonstrate a high chemical resistance against a wide variety of solvents and chemicals. The construction of the frames and the processing of the materials used exceed the highest quality standards. Our Schmidt SIGMASTAR® evaporators can be used for nearly all evaporation processes. Especially for problem products, viscous streams, slurries, and liquids with fouling tendencies, which cannot be processed with falling-film evaporators, the SIGMASTAR evaporator performs smoothly and successfully.

- Concentration of alcoholic solutions and fats and oils

- Condensation of solvents from production boilers

- Consistent system separation of media in special safety heat exchangers

- Cooling and heating of water for injection purposes (WFI) and ultra pure water

- Cooling and heating for shampoos, shower gels, fabric softeners and liquid detergents

- Cooling and heating with heat transfer oils for batch and mixing containers

- Cooling of donor blood and plasma

- Cooling of suspensions

- Cooling of surfactants

- Evaporation of water and aqueous solutions and alcohols

- Evaporation systems for traditional Chinese medicine, medicinal herb extracts, tea, coffee and a variety of extracts

- Thermal processing of essential oils

- Thermal processing of infusion solutions

Our products for Pharmaceuticals, nutraceuticals, and cosmetics

Documents

BROCHURES