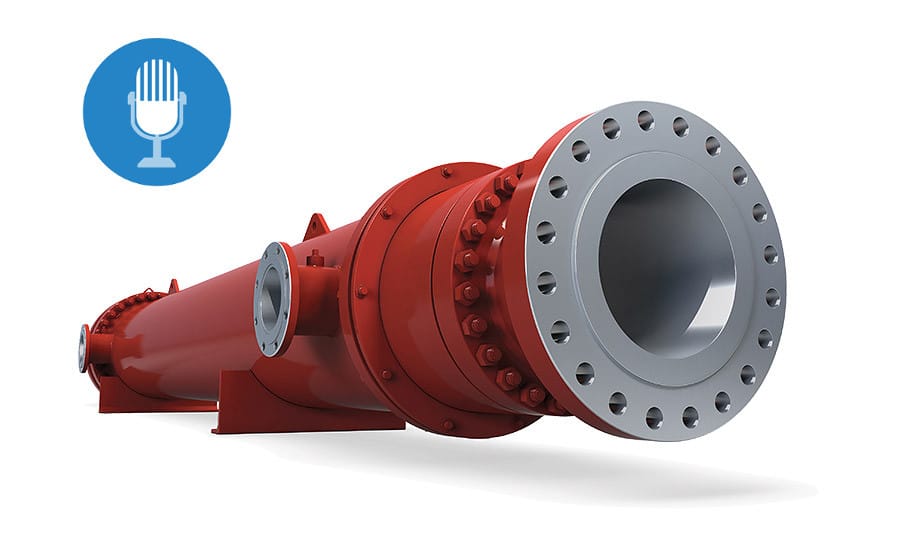

Podcast: Comparing Heat Exchanger Construction Types.

Editor Linda Becker and Austin Memmo, an application engineer with API Heat Transfer, talk about tips for selecting industrial process heat exchangers, including shell-and-tube, plate-and-frame, and shell-and plate designs.

- Austin, in your article on selecting a heat exchanger for process applications, you provide a brief overview of the general categories, including shell-and-tube, plate-and-frame, and plate and shell. Let’s talk first about some of the features each of these categories and what they might have in common. What would those be? [0:13]

- Aside from the construction method or materials of construction, what are some of the ways in which they are different? For instance, is one type more prone to fouling? [2:10]

- Though I am sure most of our listeners are familiar with shell and tube and plate and frame exchangers, you also mention plate and shell, and that this type of heat exchanger may be better able to withstand extreme temperatures and pressures. Can you tell me a bit more about it, and what type applications would be best for this type? [5:13]

- So you are able to retrofit an existing shell, putting in a laser-welded plate pack and basically keeping the hardware of a shell with the plates inside? Do you get same service in terms of pressure and temperature? [8:24]

- Are there any applications are that preclude the use of any one type of exchanger? For instance, are there any selection tips for difficult products like highly sticky or viscous fluids? [9:18]

To read the complete article, visit Improving Selecting a Process Heat Exchanger for Your Application. To listen to other episodes in this podcast series, visit www.process-cooling.com/podcasts.